产品中心 / 电镀拉丝轮

针对电镀五金工件的拉丝处理而特别设计, 拉丝快,丝路清晰,效果好,不留残胶,不留黑。柔软性及服帖性强。

Specially designed for the wire drawing treatment of electroplating hardware workpieces, it features fast wire drawing, clear wire path, good effect, no residual glue or black residue. Strong softness and adaptability.

样品展示

————————–

PRODUCT

联系我们

————————–

CONTACT

联系人:李经理

联系电话:+86-15088227166

邮箱:ellen@hx-abrasives.com

传真:+86-579-87215927

地址:浙江省永康市象珠镇清溪工业区

产品应用:

- 镀镍/锌类:

(1) 硬度选择(按镀层厚薄)一般选用5P

(2)粒度按客户的需要选用,通常细纹为240#~320#;粗纹为80#~180# 其处理的主要目的是对表面进行线纹的修饰也即为表面拉丝处理

- 汽摩件类:主要是对表面的修饰处理,达到装饰美观的作用。

- 镀铬类:由于铬的质地较硬,一般选用硬度9P及以上的抛光轮 由于镀铬后硬度很强且毛刺较多,常见的镀铬件。如:活塞环。一般使用硬度较高的产品来处理,具体规格如下:12*2 14P 320# 或12*2 16P 320# 因为毛刺较多,一道工序很难完成抛光处理,这样可根据客户的具体情况来灵活应对,如选用粗粒度的粗抛去毛刺,然后再用细粒度的精抛来满足其对工件表面光亮度的要求。

- 镀古铜类:如锁板、合页、扳手、把手、打火机等小五金工件

如枪古铜等。

(1) 软硬度选择(按镀层厚薄)一般选用4P、5P

(2)粒度按客户的需要选用,通常细纹为240#~320#;粗纹为80#~180# 做拉丝处理时应严格控制抛光机的转速,线速度应控制在15m/s左右 - Nickel/zinc plating:

(1) The hardness selection (based on the thickness of the coating) is generally 5P

(2) The granularity is selected according to the customer’s needs, usually with fine lines ranging from 240 # to 320 #; The main purpose of coarse grain processing is to modify the surface with lines, which is also known as surface wire drawing treatment

Automobile and motorcycle parts: mainly used for surface modification treatment to achieve decorative and aesthetic effects.

Chromium plating: Due to the hard texture of chromium, polishing wheels with a hardness of 9P or above are generally used. Due to the strong hardness and many burrs after chromium plating, common chromium plated parts are used. For example, piston ring. Generally, products with higher hardness are used for processing. The specific specifications are as follows: 12 * 2 14P 320 # or 12 * 2 16P 320 # . Due to the high number of burrs, it is difficult to complete polishing treatment in one process. This can be flexibly handled according to the specific situation of the customer, such as selecting coarse-grained rough polishing to remove burrs, and then using fine-grained fine polishing to meet its requirements for surface brightness of the workpiece.

Plating antique copper: such as lock plates, hinges, wrenches, handles, lighters, and other small hardware workpieces, such as gun antique copper.

(1) The selection of softness and hardness (based on the thickness of the coating) is generally 4P, 5P

(2) The granularity is selected according to the customer’s needs, usually with fine lines ranging from 240 # to 320 #; When performing wire drawing treatment with coarse lines ranging from 80 # to 180 #, the speed of the polishing machine should be strictly controlled, and the linear speed should be controlled around 15m/s

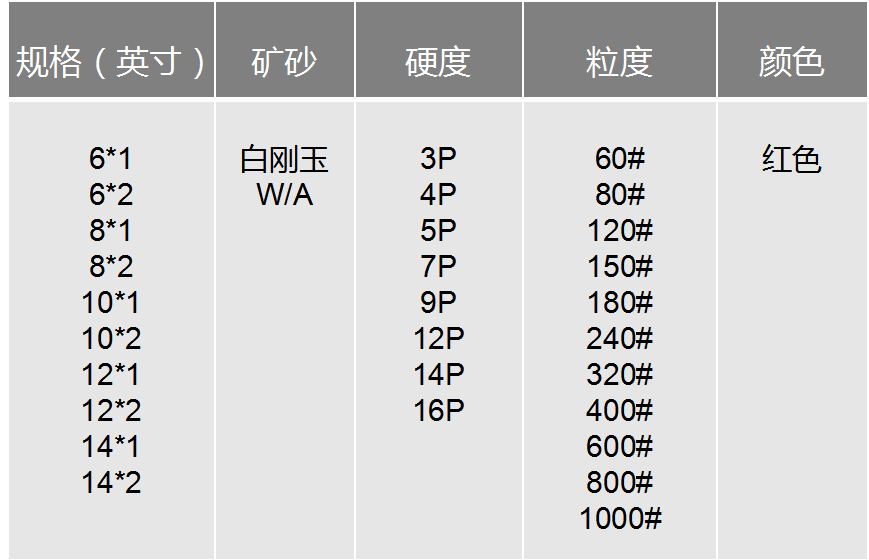

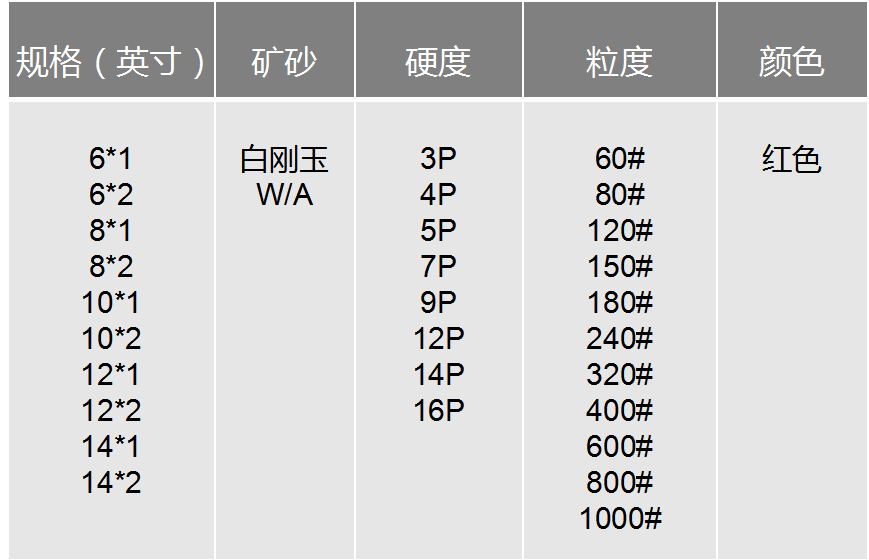

电镀拉丝轮 Preparing Wheel

针对电镀五金工件的拉丝处理而特别设计, 拉丝快,丝路清晰,效果好,不留残胶,不留黑。柔软性及服帖性强。

Specially designed for the wire drawing treatment of electroplating hardware workpieces, it features fast wire drawing, clear wire path, good effect, no residual glue or black residue. Strong softness and adaptability.

产品应用:

- 镀镍/锌类:

(1) 硬度选择(按镀层厚薄)一般选用5P

(2)粒度按客户的需要选用,通常细纹为240#~320#;粗纹为80#~180# 其处理的主要目的是对表面进行线纹的修饰也即为表面拉丝处理 - 汽摩件类:主要是对表面的修饰处理,达到装饰美观的作用。

镀铬类:由于铬的质地较硬,一般选用硬度9P及以上的抛光轮 由于镀铬后硬度很强且毛刺较多,常见的镀铬件。如:活塞环。一般使用硬度较高的产品来处理,具体规格如下:12*2 14P 320# 或12*2 16P 320# 因为毛刺较多,一道工序很难完成抛光处理,这样可根据客户的具体情况来灵活应对,如选用粗粒度的粗抛去毛刺,然后再用细粒度的精抛来满足其对工件表面光亮度的要求。 - 镀古铜类:如锁板、合页、扳手、把手、打火机等小五金工件

如枪古铜等。相匹配的三鑫产品的类型(4PB或5PB-320#)行业内称该拉丝轮为擦色轮或茶色轮。

(1) 软硬度选择(按镀层厚薄)一般选用4P、5P

(2)粒度按客户的需要选用,通常细纹为240#~320#;粗纹为80#~180# 做拉丝处理时应严格控制抛光机的转速,线速度应控制在15m/s左右 - Nickel/zinc plating:

(1) The hardness selection (based on the thickness of the coating) is generally 5P

(2) The granularity is selected according to the customer’s needs, usually with fine lines ranging from 240 # to 320 #; The main purpose of coarse grain processing is to modify the surface with lines, which is also known as surface wire drawing treatment

Automobile and motorcycle parts: mainly used for surface modification treatment to achieve decorative and aesthetic effects.

Chromium plating: Due to the hard texture of chromium, polishing wheels with a hardness of 9P or above are generally used. Due to the strong hardness and many burrs after chromium plating, common chromium plated parts are used. For example, piston ring. Generally, products with higher hardness are used for processing. The specific specifications are as follows: 12 * 2 14P 320 # or 12 * 2 16P 320 # . Due to the high number of burrs, it is difficult to complete polishing treatment in one process. This can be flexibly handled according to the specific situation of the customer, such as selecting coarse-grained rough polishing to remove burrs, and then using fine-grained fine polishing to meet its requirements for surface brightness of the workpiece.

Plating antique copper: such as lock plates, hinges, wrenches, handles, lighters, and other small hardware workpieces, such as gun antique copper.

(1) The selection of softness and hardness (based on the thickness of the coating) is generally 4P, 5P

(2) The granularity is selected according to the customer’s needs, usually with fine lines ranging from 240 # to 320 #; When performing wire drawing treatment with coarse lines ranging from 80 # to 180 #, the speed of the polishing machine should be strictly controlled, and the linear speed should be controlled around 15m/s

浙ICP备170598947号 Copyright © 2016-2019 hx-abrasives.com版权所有